SERVICES

Projects are made by people and experience

Project Management

HDS provides project management solutions to develop complete military platforms packages for marine, aerospace and land applications.

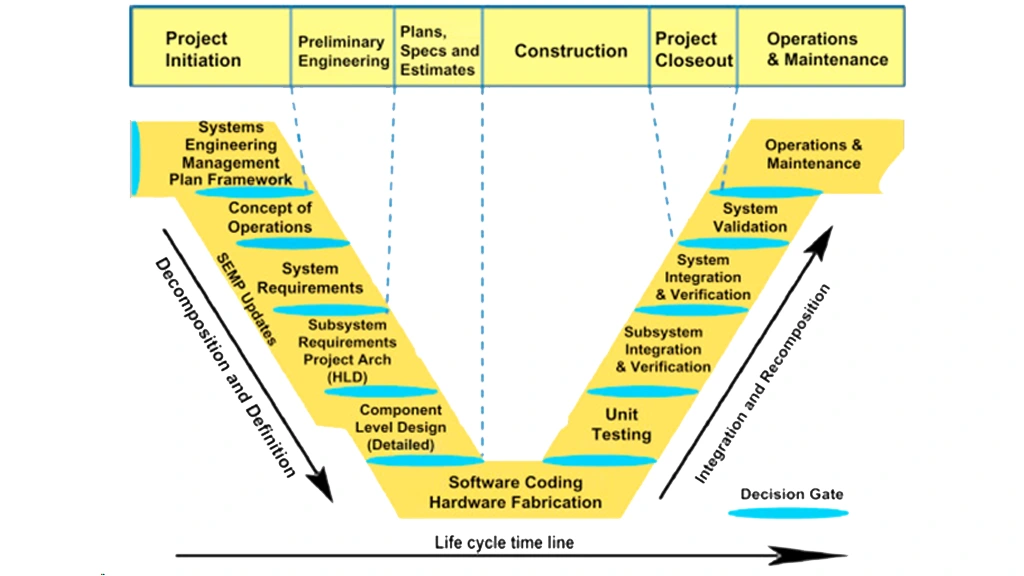

We can cover all the stages of work from requirements acquisition, preliminary concept, feasibility studies, basic design, conceptual design followed on by assistance on tender bidding, transitional design, detail design, manufacturing of main equipment and components, sub-system assemblies, testing, platform integration, performance validation, certification and final delivery.

HDS performs all these activities with full consideration of customer´s technical and commercial requirements, applicable military and industrial standards, notify bodies rules, flag authority regulations and general procedures of acquisition of military equipment and weapons systems.

Our senior experts on system engineering processes can provide technical, commercial and legal support in contractual negotiations between authorities (MOD), the final owner and operator and the main contractor and his supply chain.

Concept, Modelling and Feasibility Estudies

HDS provides research and innovative studies in the fields of synthetic design modes and optimization.

Our senior technical experts and software programmers can specify and build dedicated CONCEPT EXPLORATION MODELS (CEM) specifically tuned to suite customer´s proposed design problems. Solutions are found through open large or restricted exploration universes until feasible technical and economical options are determined and final choices are selected.

Our proprietary software tools are base on powerful data handling sources codes to manage physical data and rational design thinking to assure the use of already validated design procedures.

HDS is developing a new software tool base on AI to store our repository of knowledge.

Basic AND Detail Desing

HDS can provide design work on the following areas :

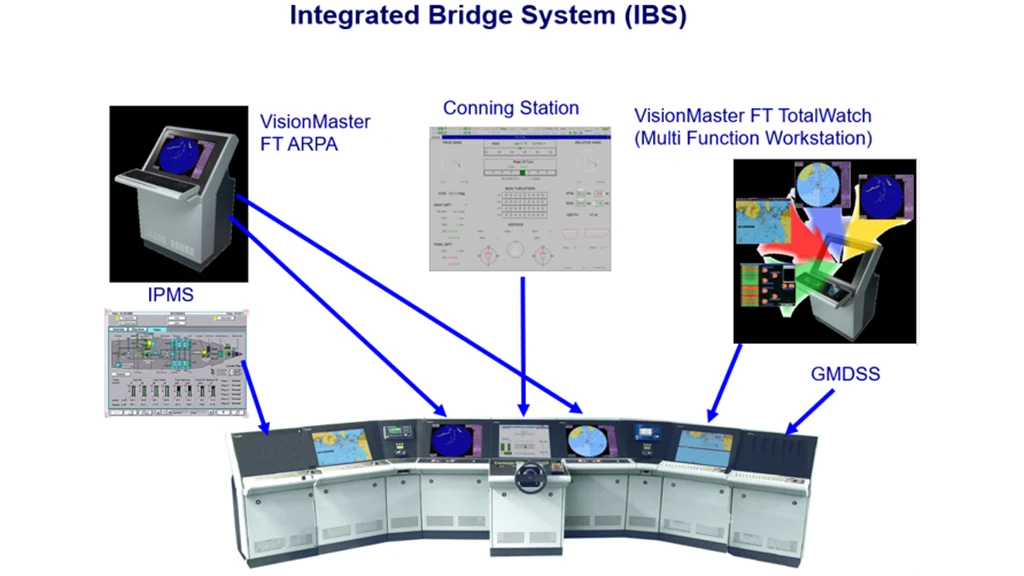

System Development AND Integration

HDS can provide design and implementation work on the following subjects:

Fabrication and Quality Assurance

HDS senior consultants and technicians can provide design and survey work on the following subjects:

VERIFICATION AND VALIDATION

BY SIMULATION AND TESTING

HDS can provide consultancy and technical survey work on the following subjects:

System Engineering

HDS works under the principals of system engineering procedures at every single step of project development by: